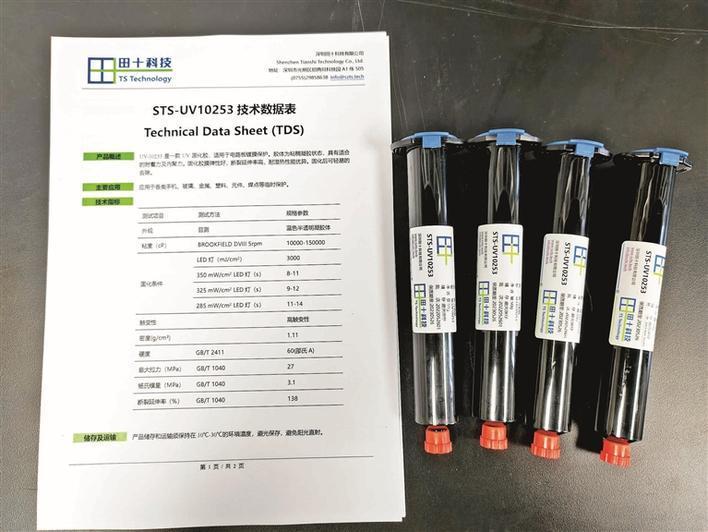

What are the characteristics of UV curing adhesive?

UV curing adhesive is a type of adhesive that can quickly dry and harden after being exposed to UV radiation. It is composed of a certain proportion of resins, photoinitiators, additives, etc. It is a glue that integrates various functions such as bonding, sealing, coating, repair, etc. Of course, it also has many advantages. UV curing adhesive can be cured using ultraviolet radiation, which requires extremely short time and greatly improves production efficiency. Due to the high molecular weight of UV curing adhesive, its density and hardness are also high after curing, which can achieve good bonding effect. When using UV light curing adhesive, it will not overflow volatile toxic substances, and will particularly adhere to the surface and solidify without disappearing. UV curing adhesive is clear and transparent, and will not turn yellow, so it will not affect the appearance quality. The interference of factors such as humidity, infrared, oxygen, etc. enables it to perform as expected in various fields, especially suitable for the production of precision instruments. In short, UV curing adhesives have the advantages of fast curing speed, high strength, environmental friendliness, and odorlessness, making them the best choice in an increasing number of industries. Before use, shake the bottle to ensure that the glue is even and do not use glue that does not flow smoothly. Wear gloves during operation to avoid contact with the skin. When using UV lamps for curing, it is necessary to maintain an appropriate distance between the lamp cap and the object to be cured, to avoid being too close or

What are the applications of UV curing adhesive

UV curing adhesive is a high-tech material that has emerged in recent years and is widely used in various fields. UV photoresist is widely used in the printing industry. Due to its rapid solidification characteristics, it greatly improves printing efficiency and can make printing colors more vivid, improving printing quality. Secondly, it also plays an important role in the production of handicrafts. Through the irradiation of UV light, the coating on the surface of handicrafts can quickly solidify, not only ensuring the aesthetics of handicrafts, but also improving their durability. In addition, it also plays an important role in the electronics industry. For example, in the process of device packaging, the use of UV photoresist can prevent electronic components from coming into contact with external gases, dust, and other substances, thereby improving the service life of electronic components. In addition, it is widely used in various fields such as the construction industry, automobile manufacturing, and medical equipment production, and its application prospects are very broad. In summary, it has a wide range of applications, especially in improving efficiency, improving quality, and enhancing product durability, with significant advantages. With the continuous development of technology, the application prospects of UV photo adhesive will become increasingly broad. UV curing adhesive is a new type of curing material with the advantages of fast curing, high hardness, impact resistance, and high transparency. The process principle of UV curing adhesive refers to

Advantages and practical applications of LED fixed crystal silver adhesive

LED solid crystal silver adhesive has the advantages of strong conductivity, rapid curing, and low viscosity, which can better improve the vertical heat transfer efficiency between LED chips and packaging materials, further enhancing the brightness and lifespan of LED lamps

Development and Application Status of LED Solid Crystal Silver Adhesive

LED solid crystal silver adhesive is a high-performance, high viscosity conductive material that plays an important role in the LED manufacturing process

Advantages and disadvantages of LED fixed crystal silver adhesive

When selecting LED solid crystal silver adhesive, attention should be paid to factors such as thermal conductivity, cooling effect, and price of the material, and suitable solid crystal silver adhesive should be selected based on the specific needs of LED products

Usage method of high-temperature curing conductive silver adhesive

High temperature cured conductive silver adhesive is a colloidal substance made of materials such as silver powder, polycarbonate resin, silicone oil, etc., with a thickness generally between 0.1mm-0.3mm, and excellent conductivity. After high-temperature treatment, its gelatinous substance can be solidified to form a hard conductive film. Strategy 1: Before using high-temperature cured conductive silver adhesive, there are several necessary preparations that need to be done first. First, two materials need to be checked, one is silver glue and the other is aluminum foil. Silver glue should be Du free, odorless, and soft; The aluminum foil should have a uniform thickness, no bubbles, and no contamination. Secondly, it is necessary to check the heat source. There are many heat sources for high-temperature curing silver adhesive, such as electric soldering iron, hot air gun, hot press, etc., depending on the thickness of the silver adhesive used. Prepare tools such as gloves, scissors, steel rulers, etc. to ensure the smooth progress of construction. Strategy 2: After the preparation work, the following are the steps to apply high-temperature cured conductive silver adhesive. Firstly, place the silver glue and aluminum foil together and compact the silver glue to ensure a seal between the silver glue and aluminum foil; Secondly, use a steel ruler to measure the distance between the silver adhesive and the aluminum foil for future use; Then, combine the silver glue and aluminum foil into a heat source, and adjust the temperature according to the different thicknesses of silver glue; Remove heat source