Application and advantages of low-temperature curing conductive silver adhesive

The Application and Advantages of Low Temperature Cured Conductive Silver Adhesive Conductive adhesive is a colloidal material with excellent conductivity, widely used in fields such as electronic equipment and solar panels. Low temperature cured conductive silver adhesive is a type of conductive adhesive that can quickly cure at low temperatures, with many unique advantages. This article will introduce the application and advantages of low-temperature cured conductive silver adhesive, and explore its potential in the electronics industry. One of the main applications of low-temperature cured conductive silver adhesive is in flexible electronic devices. With the continuous development of flexible electronic technology, traditional rigid electronic devices are gradually being replaced by flexible electronic devices. Low temperature cured conductive silver adhesive has become an ideal material for making flexible circuits due to its excellent conductivity and flexibility. By using low-temperature cured conductive silver adhesive, precise circuits can be made on flexible substrates, achieving efficient operation of flexible electronic devices. In addition, low-temperature curing conductive silver adhesive can also be applied in the manufacturing process of solar panels. Solar panels are devices that convert solar energy into electricity, and conductive adhesives play a crucial role in the production of solar panels. Low temperature cured conductive silver adhesive, as an efficient and low-cost conductive material, can be used for electrode preparation of solar panels to improve their conversion

How to choose a high conductivity silver adhesive suitable for LED packaging

How to choose a high conductivity silver adhesive suitable for LED packaging? In today's technological development, LED products are gradually replacing traditional lighting equipment as the main light source in people's lives. In the manufacturing process of LED, high conductivity silver glue is widely used for circuit connections in LED packaging. Choosing a high conductivity silver adhesive suitable for LED packaging is an important step in ensuring product quality and performance. This article will introduce how to choose a high conductivity silver adhesive suitable for LED packaging and help you understand the relevant knowledge and skills. Firstly, understanding the characteristics and advantages of high conductivity silver adhesive is the basis for selecting suitable products. High conductivity silver glue has excellent conductivity, which can effectively conduct current, improve the performance stability and luminous efficiency of LED products. In addition, high conductivity silver adhesive also has excellent thermal conductivity and high temperature resistance, which can maintain stable performance in high temperature environments and extend the service life of LED products. Secondly, select a suitable high conductivity silver adhesive based on the specific requirements of LED packaging. LED packaging involves different processes and materials, so it is necessary to choose appropriate high conductivity silver adhesive based on different application scenarios and packaging requirements. For example, in high-power LED packaging, it is necessary to choose high thermal conductivity and high temperature resistance

High conductivity silver glue: a new darling in the field of electronic assembly

High conductivity silver glue: a new darling in the field of electronic assembly. With the continuous development of technology, the field of electronic assembly is also constantly moving forward. In this field, high conductivity silver glue has become a highly sought after new darling. Its excellent conductivity and multifunctional properties make it an indispensable material in the electronics industry. This article will delve into the characteristics, applications, and future development prospects of high conductivity silver adhesives. Firstly, let's understand the characteristics of high conductivity silver glue. High conductivity silver adhesive is a bonding material with good conductivity, composed of silver nanoparticles and organic matrix. This silver adhesive has received widespread attention due to its superior conductivity. Compared to traditional silver conductive adhesives, high conductivity silver adhesives not only have higher conductivity, but also better adhesive performance and heat resistance. This makes it widely applicable in circuit connection, packaging, and repair during electronic assembly processes. High conductivity silver glue has a wide range of applications in the field of electronic assembly. Firstly, it can be used for circuit connections. In the manufacturing process of electronic equipment, circuit connection is a very crucial link. Traditional welding methods require high temperatures and harmful soldering agents, while high conductivity silver adhesive can be easily coated or sprayed to achieve circuit connection, avoiding traditional welding

Efficient conductive bonding solution: Shenzhen TS Materials solves the electronic assembly problem for you. In the electronic industry, chip solidification is a key link, and efficient conductive bonding solution can provide a way to solve the problem for electronic assembly. Shenzhen TS Materials, as a company specializing in efficient and conductive bonding solutions, provides customers with high-quality chip fixed crystal silver adhesives to assist in the smooth progress of electronic assembly. Chip fixed crystal silver adhesive is a highly conductive adhesive that can firmly fix chips onto circuit boards and ensure good conductivity. It plays a crucial role in electronic assembly, and Shenzhen TS Materials, with its rich experience and professional knowledge, provides customers with efficient and conductive bonding solutions, helping them solve the problems in the electronic assembly process. Shenzhen TS Materials's chip fixed crystal silver adhesive has the following characteristics: 1 Excellent conductivity: The chip fixed crystal silver adhesive has good conductivity, which can ensure the stability and reliability of electronic assembly. 2. High bonding strength: The chip crystal silver adhesive can firmly fix the chip on the circuit board, avoiding looseness or detachment during the assembly process. 3. Good high-temperature resistance: The chip fixed crystal silver adhesive can maintain stable performance in high-temperature environments and will not be affected by temperature changes

Chip fixed crystal silver glue: improving the reliability and stability of electronic assembly

Chip fixed crystal silver adhesive is a widely used material in electronic assembly processes, which can improve the reliability and stability of electronic devices. This article will delve into the characteristics and advantages of chip fixed crystal silver glue, and introduce its application in the electronics industry. With the continuous development of electronic devices, the requirements for reliability and stability in the electronic assembly process are also increasing. Chip fixed crystal silver adhesive, as a high-performance material, is increasingly receiving attention and adoption from electronic manufacturers. It can provide good conductivity and thermal conductivity, as well as excellent adhesion and heat resistance, enabling a tight connection between the chip and substrate, effectively preventing loosening and fracture caused by temperature changes and mechanical stress. The application range of chip fixed crystal silver glue is wide, covering various electronic devices, such as smartphones, tablets, televisions, and automotive electronics. In these devices, chip fixed crystal silver glue can be used to fix the connection between the chip and the substrate, ensuring their stable operation in complex environments. At the same time, chip fixed crystal silver glue can also improve the heat dissipation performance of electronic devices, effectively reduce the impact of temperature on the chip, and protect the normal operation of the chip. In addition to its application in electronic devices, chip fixed crystal silver glue is also widely used in research and development in the electronic assembly industry. It can be used as a heavy

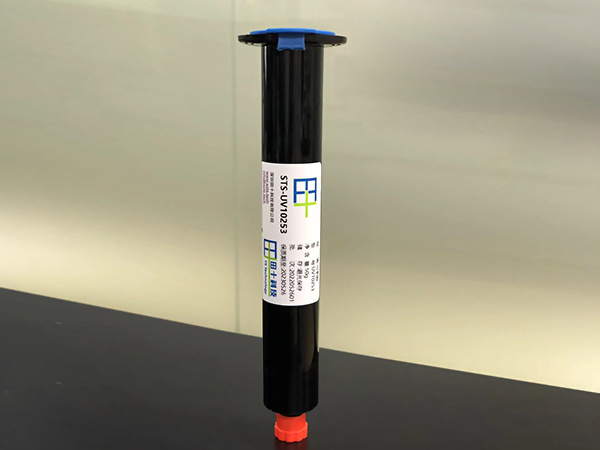

Introduction to precautions for UV curing adhesive, come and collect it!

UV curing adhesive is a new type of environmentally friendly material with many unique characteristics, gradually being widely used in various industries. 1. Quick curing. The curing speed of UV curing adhesive is very fast, usually taking only a few seconds or minutes to cure, thereby significantly improving production efficiency. 2. High viscosity. UV light curing adhesive has a high viscosity and can firmly bond various materials, such as metal, glass, plastic, and paper. 3. Environmentally friendly and pollution-free. UV light curing adhesive does not contain organic volatiles, does not produce harmful gases and pollutants, and does not have an impact on the environment, meeting modern environmental requirements. 4. High strength and durability. After curing, UV curing adhesive has extremely high strength and durability, and can withstand various complex environments and conditions. 5. Widely used. UV light curing adhesive can be applied in various fields such as electronics, healthcare, food, cosmetics, papermaking, printing, and automotive manufacturing. 6. Low cost and high efficiency. The cost of UV curing adhesive is relatively low, and it can improve production efficiency and reduce production costs, therefore it has very high economic value. In short, as a new type of material, UV light curing adhesive has very unique characteristics and a wide range of applications, so it has a very broad market and prospects in future development and applications. Using UV curing adhesive